Diffuson Coatech

A deep tech surface engineering company providing wear and corrosion resistant coatings and diffusions to enhance the product durability.

Solutions offered:

- MetaBoid

- Chromizing

- Aluminizing

- Boronizing

- Electroless Nickel Boron

What is MetaBoid ?

A hybrid (Thermal diffusion-Chemical vapor deposition) process

MetaBoid is a thermochemical vapor diffusion process producing metal compounds with the substrate material. The surface hardness is easily 3X higher than nitriding process.

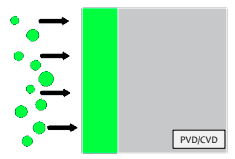

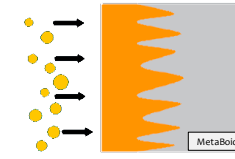

Vapor deposition and Vapor diffusion comparison

- High chances of delamination

- High stress on the interface

- A functional layer is developed on the steel surface

- May require a interface layer

- High adhesion strength

- Forms compounds with the base metal

- Thermal stability

- High bonding strength

Friction

This process reduces the coefficient

of friction of the base material

without the use of any lubricant.

Wear resistance

By altering the chemistry of surface of a material with minimal effect on core micro-structure to produce

hard case through a process called surface alloying by diffusion.

Corrosion resistance

Salt spray tests indicate increased

corrosion resistance in ferrous

alloys. Remarkable resistance to

acid attack has been observed in

treated carbon steel.

MetaBoid & TUNGSTEN CARBIDE

MetaBoid is a diffusion coating with practically

infinite bonding strength with zero chance of delamination

Extremely high hardness,

can be achieved. (2200 HV+)

1.8 times higher wear resistance

Least surface roughness. Heat resistance up to 625 °C.

Resistance against HCl, and other acids.

Relatively lower cost.

Tungsten carbide based coatings are mostly sprayed

onto metal and have very low bonding strength and often delaminate

possible. Maximum hardness

is 1300 HV only

High surface roughness, often grinding is required.

Lower temperature resistance little resistance to acids

Expensive (Minimum Rs. 35/ Sq. Inch)

Contact Details